Laser Level How to Use and Maintain

Tool55Plus: How to Use and Maintain Your Laser Level in the U.S. Market

Laser levels have become essential tools for construction crews, contractors, and even DIY homeowners in the U.S. They provide accurate reference points for layout, alignment, and finishing work—both indoors and outdoors. At Tool55Plus, we focus on making sure our customers not only get reliable tools but also know how to use and care for them properly.

This guide will walk you through operation, safety tips, maintenance, and troubleshooting for your Tool55Plus Laser Level, so you can get maximum accuracy and extend the life of your investment.

How to Operate Your Tool55Plus Laser Level

Pre-Use Checks

Before switching on your laser level, inspect the casing and lenses for any cracks or dirt, make sure all attachments are tight, and confirm the battery is fully charged or have a spare ready.

Powering On

Press and hold the power button for a few seconds until the system runs its internal check. The laser will stabilize automatically, projecting a clean and precise beam.

Leveling and Setup

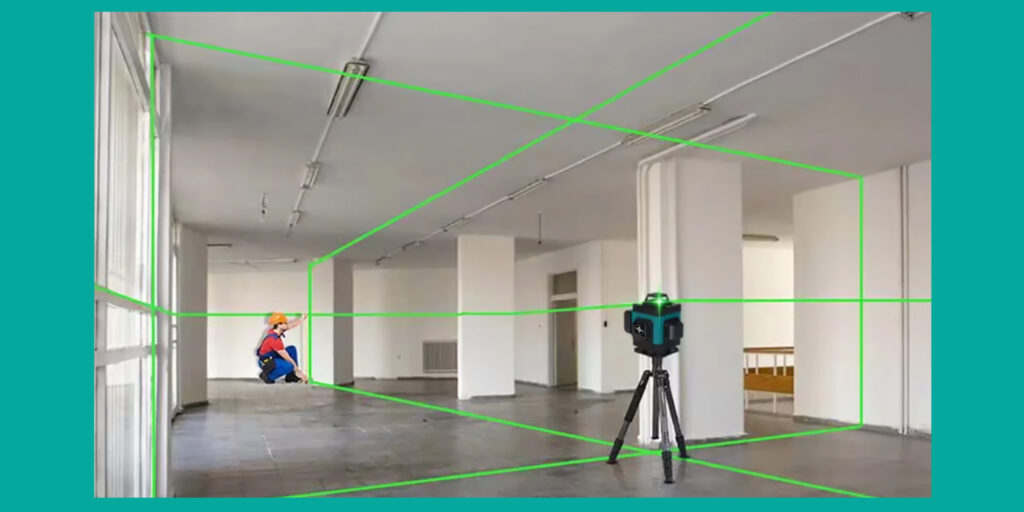

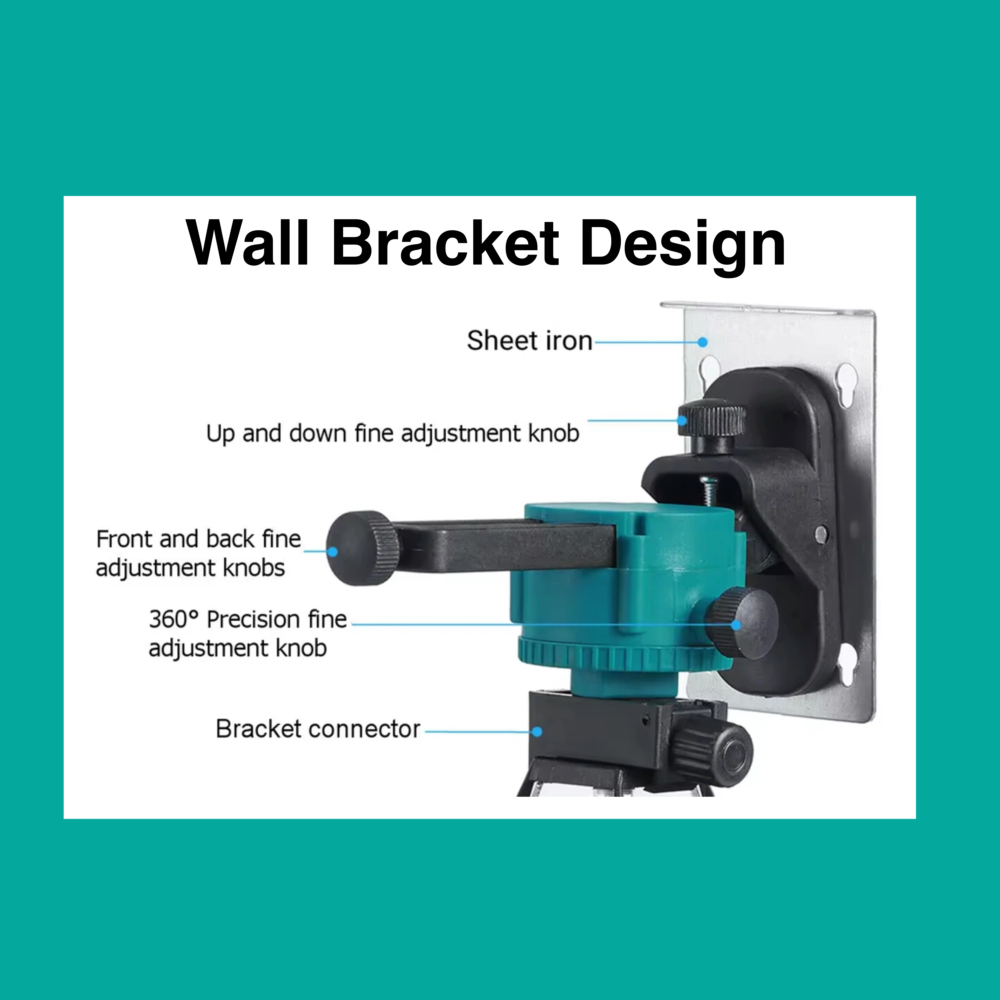

Mount the laser securely on a tripod or a flat surface. The automatic leveling function ensures accuracy within range, and if the tool tilts too much, it will flash as a warning until you readjust it.

Using Line Modes

Depending on your model, you can select horizontal line mode for wall leveling or multi-line mode for full-room layouts and framing.

Safety Tips When Using a Laser Level

Eye Protection

Always wear protective glasses when operating the laser. Avoid looking directly into the beam and never point it at people or pets.

Battery Safety

Use the provided charger and do not allow the battery to overheat. Store extra batteries safely and away from objects that could cause a short circuit.

Work Environment

Avoid using the device in explosive or highly flammable areas. Keep the tripod stable and prevent vibrations or impacts that could affect precision.

Maintenance for Long-Term Performance

Cleaning

Clean the lens with a microfiber cloth to keep projections accurate.

Storage

Store the device in a dry, cool place. Remove the battery if you are not using the tool for an extended time and keep the unit in its protective case.

Calibration

Calibrate your laser level every six months to ensure measurement accuracy.

Battery Care

Do not allow the battery to fully discharge frequently. If storing long-term, keep it charged between 40 and 60 percent.

Troubleshooting Common Issues

Unstable Laser Beam

Check the stability of the surface, clean the lens, and tighten any loose parts.

No Power or Display

Confirm that the battery is charged and seated correctly. If it remains unresponsive, test with another battery.

Accuracy Problems

If your lines appear consistently off, the unit may need calibration.

Loose Components

Vibrations or drops can cause parts to loosen. Re-secure them carefully and contact Tool55Plus if you need replacement parts.

Frequently Asked Questions

How long does the battery last?

A fully charged lithium-ion battery can operate for several hours depending on the mode selected.

Can I use the laser level outdoors?

Yes, Tool55Plus laser levels are designed for both indoor and outdoor use, though strong sunlight may affect visibility.

How often should I calibrate my laser level?

Calibration is recommended every six months, or sooner if you notice inconsistent measurements.

Final Thoughts

At Tool55Plus, we believe precision tools require proper use and care. By following these operating guidelines, safety practices, and maintenance routines, your laser level will remain accurate and reliable for years.

Whether you are a contractor, workshop owner, or DIY enthusiast, Tool55Plus offers the reliability, performance, and U.S.-based support you need to work with confidence.